Mailbox:info@chinaleadtop.com Business Phone : 86-0577-65158955

Focusing on the production of solid pharmaceutical preparations, granulation is an important process

- Categories:Technical Articles

- Author:

- Origin:

- Time of issue:2021-01-05 09:35

- Views:0

(Summary description)There are many kinds of drugs, which can be divided into solid, semi-solid, liquid and gas dosage forms. Among them, solid preparation accounts for about 70% of all drugs, which is the main dosage form of drugs. It has the advantages of good physical and chemical stability, low production cost, easy to take and carry, so it is welcomed by patients.

Focusing on the production of solid pharmaceutical preparations, granulation is an important process

(Summary description)There are many kinds of drugs, which can be divided into solid, semi-solid, liquid and gas dosage forms. Among them, solid preparation accounts for about 70% of all drugs, which is the main dosage form of drugs. It has the advantages of good physical and chemical stability, low production cost, easy to take and carry, so it is welcomed by patients.

- Categories:Technical Articles

- Author:

- Origin:

- Time of issue:2021-01-05 09:35

- Views:0

Focusing on the production of solid pharmaceutical preparations, granulation is an important process

There are many kinds of drugs, which can be divided into solid, semi-solid, liquid and gas dosage forms. Among them, solid preparation accounts for about 70% of all drugs, which is the main dosage form of drugs. It has the advantages of good physical and chemical stability, low production cost, easy to take and carry, so it is welcomed by patients.

Drug solid preparation is based on drug powder as the starting material. In order to ensure the product quality and smooth production process of solid preparation, it is often necessary to process and treat drugs, such as crushing, grading, mixing, granulation, drying, tablet pressing, etc. In the production process of solid pharmaceutical preparations, granulation is a very important process.

According to the understanding of the traditional granulation process, it is easy to use the mixing drying oven to affect the product quality. In order to strengthen the supervision and management of drug production and drug quality, and ensure the safety of patients, China has implemented the GMP certification system. Under this system, the design of plant and equipment configuration, water, ventilation and air conditioning system, warehouse conditions, production management and quality management file system, organization and other aspects are facing more stringent requirements It also includes the requirement to prevent cross contamination.

In this context, the traditional granulation process obviously can not meet the requirements of certification enterprises, and gradually become unpopular, and a new "efficient wet granulation boiling drying" production process was born, its obvious characteristics are: high production efficiency, short cycle, and in line with GMP requirements, at present this new granulation process is widely recognized and applied by pharmaceutical enterprises.

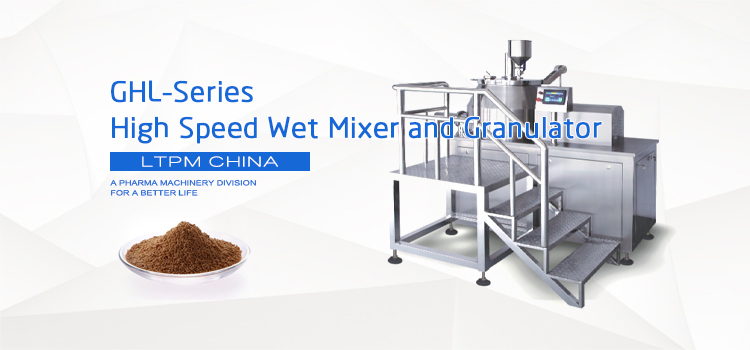

The production process of "high efficiency wet granulation boiling drying" includes two parts: high efficiency wet granulation and boiling drying. The high efficiency wet granulation refers to the granulation process of mixing humidifying stirring high speed cutting granulation in the same equipment container, which is characterized by avoiding cross pollution, convenient operation, reducing labor intensity and meeting the GMP requirements. The boiling drying is the best process The dried granular material is in boiling state in the clean hot air flow. Through the heat exchange between the hot air and the material, the rapid drying of the material is realized.

It is worth mentioning that although the advantages of the new pelletizing process are prominent, the key to the normal use of the new process equipment is the success of debugging. Many users report that the quality problems such as "too many material heads" often appear in the commissioning process of the wet granulation and boiling drying equipment, which seriously affect the granulation effect.

In order to solve the quality problem of "too many material heads" in the trial production and commissioning, some domestic manufacturers also start from the working principle of wet granulation and boiling drying, combined with the traditional granulation process, test and analyze the boiling drying, discuss the commissioning work of new wet granulation and boiling drying equipment, and improve the problems in the commissioning of the equipment.

For example, a granulator manufacturer found that the key to debugging the equipment is to make the material flow fully by discussing the problems existing in the production and debugging of the equipment. Therefore, after the efficient wet granulation, the manufacturer added a wet granulation procedure to enhance the fluidity of the material. At the same time, the manufacturer also improved the operation procedure, so that after the fan started, the material was heated first and then fed, which reduced the phenomenon of material re aggregation after entering the dryer chamber.

Some companies have designed the wet granulation boiling drying line unit by widely absorbing and combining with the production process characteristics of solid preparations at home and abroad. It is a new type of machine which combines the wet granulation machine, wet granulation machine, boiling dryer, dry granulation machine, material conveying, mixer, etc. effectively, and combines with the actual domestic production demand. It has reasonable structure, stable performance and high reliability It avoids the problem of "too many material heads", and is suitable for the production of tablets, capsules and granules.

In general, under the background of aging and consumption upgrading, the market demand for solid pharmaceutical preparations will continue to grow. At the same time, as the industry supervision becomes stricter and the quality requirements continue to improve, the production process and equipment related to solid pharmaceutical preparations also need to keep pace with the times and constantly upgrade to meet the production requirements of higher quality products.

Scan the QR code to read on your phone

Add:LTPM CHINA 2nd Floor,Dongxin Road and 5th Development Road ,Caizhai Industrial Zone, Ruian City, Zhejing Province ,China

Tel:86-0577-65158955 Fax: 86-0577-65158944

Business Phone : 86-0577-65158955

E-mail:info@chinaleadtop.com

About Us

Contact Us

LeadTop Pharmaceutical Machinery Co., LTD 浙ICP备16043185号-1

LeadTop Pharmaceutical Machinery Co., LTD 浙ICP备20003428号-1