Mailbox:info@chinaleadtop.com Business Phone : 86-0577-65158955

GFG-100 High Efficiency Boiling Dryer

GFG-100 High Efficiency Boiling Dryer

Application:

1.Drying for wet granules and powder materials of screw extruded granules, swaying granules, high-speed mixing granulation in the fields such as Pharmacy, food, feed, chemical industry and so on.

2.Large granules, small block, viscous block granular materials.

3.The materials such as Konjak, polyacry lamide and so on , which will have the volume changed during drying.

Principle:

After air is purified and heated, then it will be introduced from the bottom of induced-draft fan and passed through the screen plate of raw material. In working chamber, the state of fluidization is formed through stirring and negative effect. The moisture is evaporated and removed rapidly and the raw material is dried quickly.

Feature:

- Fluidized bed is round so that to avoid the dead corner.

- Inside the bed has installed a mixer, so that to avoid damp materials agglomerating and the channeling during drying.

- The cloth-bag filter at the top is made of the special antistatic fibers to ensure the safety of the operation.

- Overturning ischarge of the machine is convenient, quick and complete.

- Operated at sealed negative pressure and designed by GMP.

- This equipment can be designed and manufactured to be feeding and discharging automatically as requirements.

Machine Installation and Working Staff:

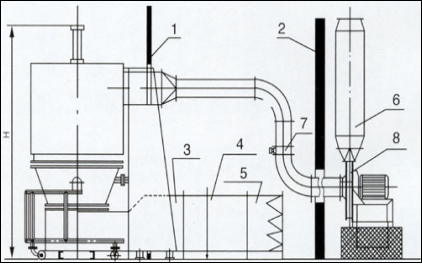

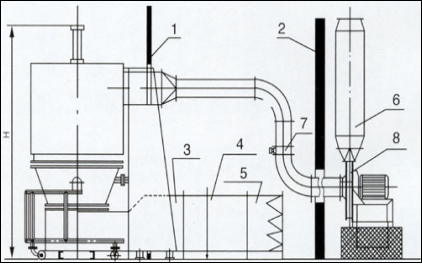

1. Partition Board 2. Partition Board 3. Heating Equipment 4. Air Filter 5. Air Filter 6. Muffler 7. Air Adjust Valve 8. Exhaust Motor

1. Partition Board 2. Partition Board 3. Heating Equipment 4. Air Filter 5. Air Filter 6. Muffler 7. Air Adjust Valve 8. Exhaust Motor

Main Technical Data

| Item | Model | ||||||

| Amount of feed (kg) | 60 | 100 | 120 | 150 | 200 | 300 | 500 |

| Flow of fan | 3530 | 3650 | 3650 | 4901 | 6032 | 7800 | 1080 |

| Power of fan (kw) | 7.5 | 11 | 11 | 15 | 22 | 30 | 45 |

| Power of stirring (kw) | 0.75 | 1.1 | 1.1 | 1.1 | 1.5 | 1.5 | 1.5 |

| Rotation of stirring (rpm) | 11 | 11 | 11 | 11 | 11 | 11 | 11 |

| Steam consume (kg/h) | 141 | 170 | 170 | 240 | 282 | 366 | 451 |

| Operate time (min) | 15-30 | 15-30 | 15-30 | 15-30 | 15-30 | 15-30 | 15-30 |

| Height (mm) | 2700 | 2900 | 2900 | 2900 | 3100 | 3600 | 3850 |

GFG-100 High Efficiency Boiling Dryer

Application:

1.Drying for wet granules and powder materials of screw extruded granules, swaying granules, high-speed mixing granulation in the fields such as Pharmacy, food, feed, chemical industry and so on.

2.Large granules, small block, viscous block granular materials.

3.The materials such as Konjak, polyacry lamide and so on , which will have the volume changed during drying.

Principle:

After air is purified and heated, then it will be introduced from the bottom of induced-draft fan and passed through the screen plate of raw material. In working chamber, the state of fluidization is formed through stirring and negative effect. The moisture is evaporated and removed rapidly and the raw material is dried quickly.

Feature:

- Fluidized bed is round so that to avoid the dead corner.

- Inside the bed has installed a mixer, so that to avoid damp materials agglomerating and the channeling during drying.

- The cloth-bag filter at the top is made of the special antistatic fibers to ensure the safety of the operation.

- Overturning ischarge of the machine is convenient, quick and complete.

- Operated at sealed negative pressure and designed by GMP.

- This equipment can be designed and manufactured to be feeding and discharging automatically as requirements.

Machine Installation and Working Staff:

1. Partition Board 2. Partition Board 3. Heating Equipment 4. Air Filter 5. Air Filter 6. Muffler 7. Air Adjust Valve 8. Exhaust Motor

1. Partition Board 2. Partition Board 3. Heating Equipment 4. Air Filter 5. Air Filter 6. Muffler 7. Air Adjust Valve 8. Exhaust Motor

Main Technical Data

| Item | Model | ||||||

| Amount of feed (kg) | 60 | 100 | 120 | 150 | 200 | 300 | 500 |

| Flow of fan | 3530 | 3650 | 3650 | 4901 | 6032 | 7800 | 1080 |

| Power of fan (kw) | 7.5 | 11 | 11 | 15 | 22 | 30 | 45 |

| Power of stirring (kw) | 0.75 | 1.1 | 1.1 | 1.1 | 1.5 | 1.5 | 1.5 |

| Rotation of stirring (rpm) | 11 | 11 | 11 | 11 | 11 | 11 | 11 |

| Steam consume (kg/h) | 141 | 170 | 170 | 240 | 282 | 366 | 451 |

| Operate time (min) | 15-30 | 15-30 | 15-30 | 15-30 | 15-30 | 15-30 | 15-30 |

| Height (mm) | 2700 | 2900 | 2900 | 2900 | 3100 | 3600 | 3850 |

Add:LTPM CHINA 2nd Floor,Dongxin Road and 5th Development Road ,Caizhai Industrial Zone, Ruian City, Zhejing Province ,China

Tel:86-0577-65158955 Fax: 86-0577-65158944

Business Phone : 86-0577-65158955

E-mail:info@chinaleadtop.com

About Us

Contact Us

LeadTop Pharmaceutical Machinery Co., LTD 浙ICP备16043185号-1

LeadTop Pharmaceutical Machinery Co., LTD 浙ICP备20003428号-1