Mailbox:info@chinaleadtop.com service@ltpmchina.com Business Phone : 86-0577-65158955

LPG-300 High Speed Centrifugal Spray Drying Machine

LPG-300 High Speed Centrifugal Spray Drying Machine

Introduction:

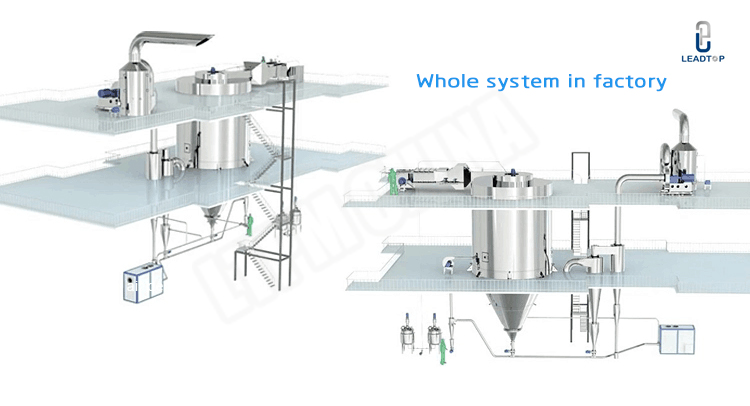

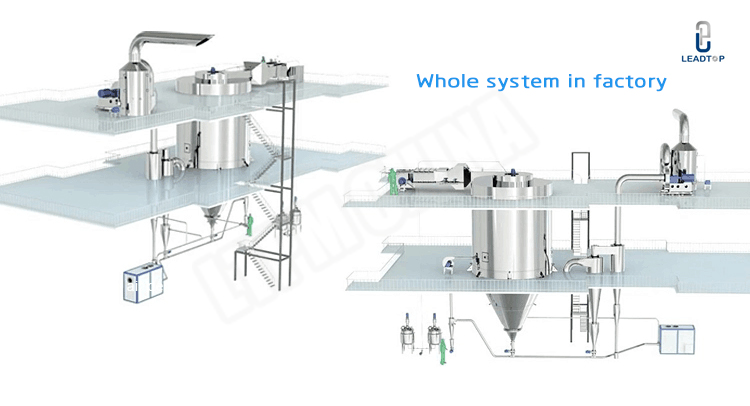

Spray drying is the widest used technology in the liquid shaping technology and in the drying industry. Centrifugal Atomizing (Spray) Drying Equipment is most suitable for producing powder, particles or solid block products from materials of solution, emulsion, soliquoid and pumpable paste states. Therefore, spray drying is useful to create the desired particle size, residual water contents, the stocking density, and the particle shape needed to meet precise standards

Working Principle:

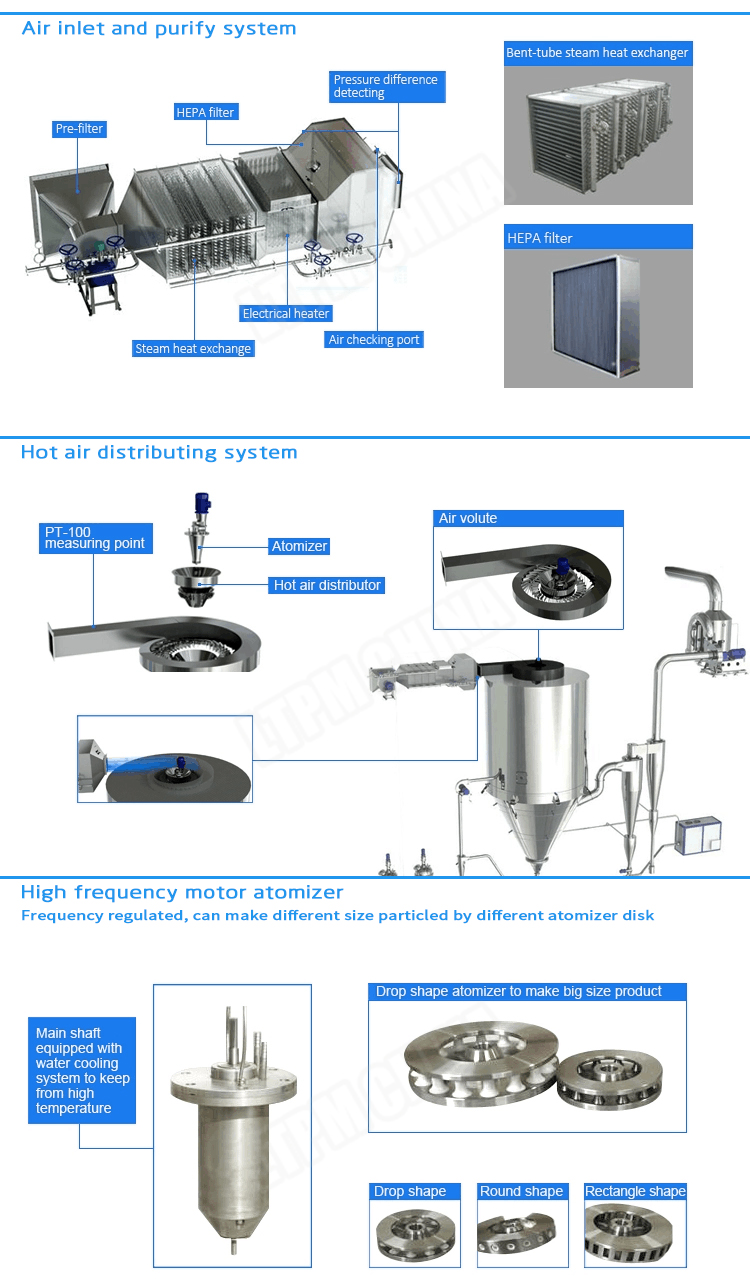

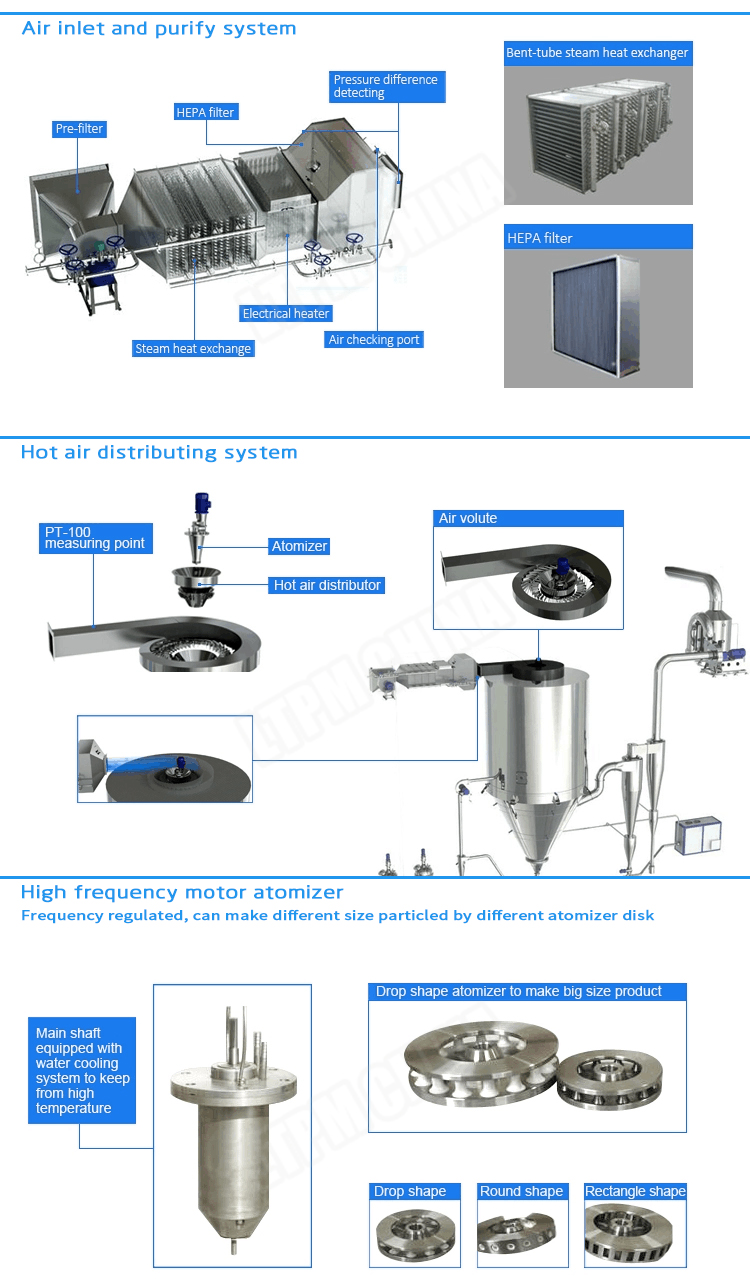

The air is through the filter and heater, the air distributor which enters the dedicator top, the hot air takes the form of spiral and enters the dedicator evenly. The material liquid , from the material liquid trough from the at odds with the community or the leadership atomizer for the dedicator top of pump sending through the filter, make the material liquid gush out into an extremely small calorific drop, material liquid and hot air flow and keep in touch, moisture evaporate rapidly, within extremely short time dry to become finished product, finished product discharge by dry tower bottom and whirlwind separator, the waste gas is discharged by the air blower.

Technical Parameters

| Model | 5 | 10 | 15 | 20 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6500 | |

| Inlet Temperature | 140-350 automatically controlled | ||||||||||||||||

| Outlet Temperature(℃) | 80-90 | ||||||||||||||||

| Water evaporation capacity(kg/h) | 5 | 10 | 15 | 20 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6000 | |

| Diameter of atomizing tray(rpm) | 50 | 80 | 80 | 120 | 120 | 120 | 120 | 150 | 150 | 150 | 180-210 | Accordance with the requirement of process | |||||

| Max Electric heating power(kw) | 12 | 24 | 36 | 45 | 46 | 63 | 81 | 99 | |||||||||

| Dried powder restoring rate | ≥95 | ||||||||||||||||

| Length of covered area(m) | 1.6 | 2.7 | 3 | 3.5 | 4 | 4.5 | 5.2 | 7 | 7.5 | 12.5 | 13.5 | 14.5 | Decided in accordance the flow chart | ||||

| Width of covered area(m) | 1.1 | 1.5 | 1.8 | 2 | 2.7 | 2.8 | 3.5 | 5.5 | 6 | 8 | 12 | 14 | ??Condition of field and requirement | ||||

LPG-300 High Speed Centrifugal Spray Drying Machine

Introduction:

Spray drying is the widest used technology in the liquid shaping technology and in the drying industry. Centrifugal Atomizing (Spray) Drying Equipment is most suitable for producing powder, particles or solid block products from materials of solution, emulsion, soliquoid and pumpable paste states. Therefore, spray drying is useful to create the desired particle size, residual water contents, the stocking density, and the particle shape needed to meet precise standards

Working Principle:

The air is through the filter and heater, the air distributor which enters the dedicator top, the hot air takes the form of spiral and enters the dedicator evenly. The material liquid , from the material liquid trough from the at odds with the community or the leadership atomizer for the dedicator top of pump sending through the filter, make the material liquid gush out into an extremely small calorific drop, material liquid and hot air flow and keep in touch, moisture evaporate rapidly, within extremely short time dry to become finished product, finished product discharge by dry tower bottom and whirlwind separator, the waste gas is discharged by the air blower.

Technical Parameters

| Model | 5 | 10 | 15 | 20 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6500 | |

| Inlet Temperature | 140-350 automatically controlled | ||||||||||||||||

| Outlet Temperature(℃) | 80-90 | ||||||||||||||||

| Water evaporation capacity(kg/h) | 5 | 10 | 15 | 20 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6000 | |

| Diameter of atomizing tray(rpm) | 50 | 80 | 80 | 120 | 120 | 120 | 120 | 150 | 150 | 150 | 180-210 | Accordance with the requirement of process | |||||

| Max Electric heating power(kw) | 12 | 24 | 36 | 45 | 46 | 63 | 81 | 99 | |||||||||

| Dried powder restoring rate | ≥95 | ||||||||||||||||

| Length of covered area(m) | 1.6 | 2.7 | 3 | 3.5 | 4 | 4.5 | 5.2 | 7 | 7.5 | 12.5 | 13.5 | 14.5 | Decided in accordance the flow chart | ||||

| Width of covered area(m) | 1.1 | 1.5 | 1.8 | 2 | 2.7 | 2.8 | 3.5 | 5.5 | 6 | 8 | 12 | 14 | ??Condition of field and requirement | ||||

Add:LTPM CHINA 2nd Floor,Dongxin Road and 5th Development Road ,Caizhai Industrial Zone, Ruian City, Zhejing Province ,China

Tel:86-0577-65158955 Fax: 86-0577-65158944

Business Phone : 86-0577-65158955

E-mail:info@chinaleadtop.com service@ltpmchina.com

About Us

Contact Us

LeadTop Pharmaceutical Machinery Co., LTD 浙ICP备16043185号-1

LeadTop Pharmaceutical Machinery Co., LTD 浙ICP备20003428号-1