Mailbox:info@chinaleadtop.com Business Phone : 86-0577-65158955

LTHH-B High Speed Folding Gluing Machine

LTHH-B High Speed Folding Gluing Machine

Product introduction:

Series B Model A 2-fold folding gluing machine is Pre-fold amchine, adopt synchronous belt transmission and electronic continuously variable speeder ,domestic standard electronic components,feeding section adopt mechanic continuously variable, stable and easy to control and operate. It is widely used in food, medicine, cosmetics, stationery and other ordinary cartons, process and perfectly combing the requirements of auto packaging together. (in case of any special function required, we can design according to the customer’s requirement).

Feature introduction:

The Machine consists of 5 sections: feeding, pre-folding , final folding, full-press and transmission.

Technical Data:

|

Name |

LTHH-650B pre-folding Gluing Machine |

| Model |

LTHH-650B |

|

Paper Material |

Cardboard 210-800g |

|

Max. Liner speed |

Max. 220 m/min |

|

Feeding way |

Automatically and continuously feeding |

|

Way of folding |

Fold 1 and fold 3 are 180°, fold 2 and fold 4 are 135°and 180° |

|

Glue Material |

Water-base cold glue |

|

Electric power |

6.0kw 380v |

|

Weight |

2.3T |

|

Over dimension |

8.2x1.3x1.45m |

|

|

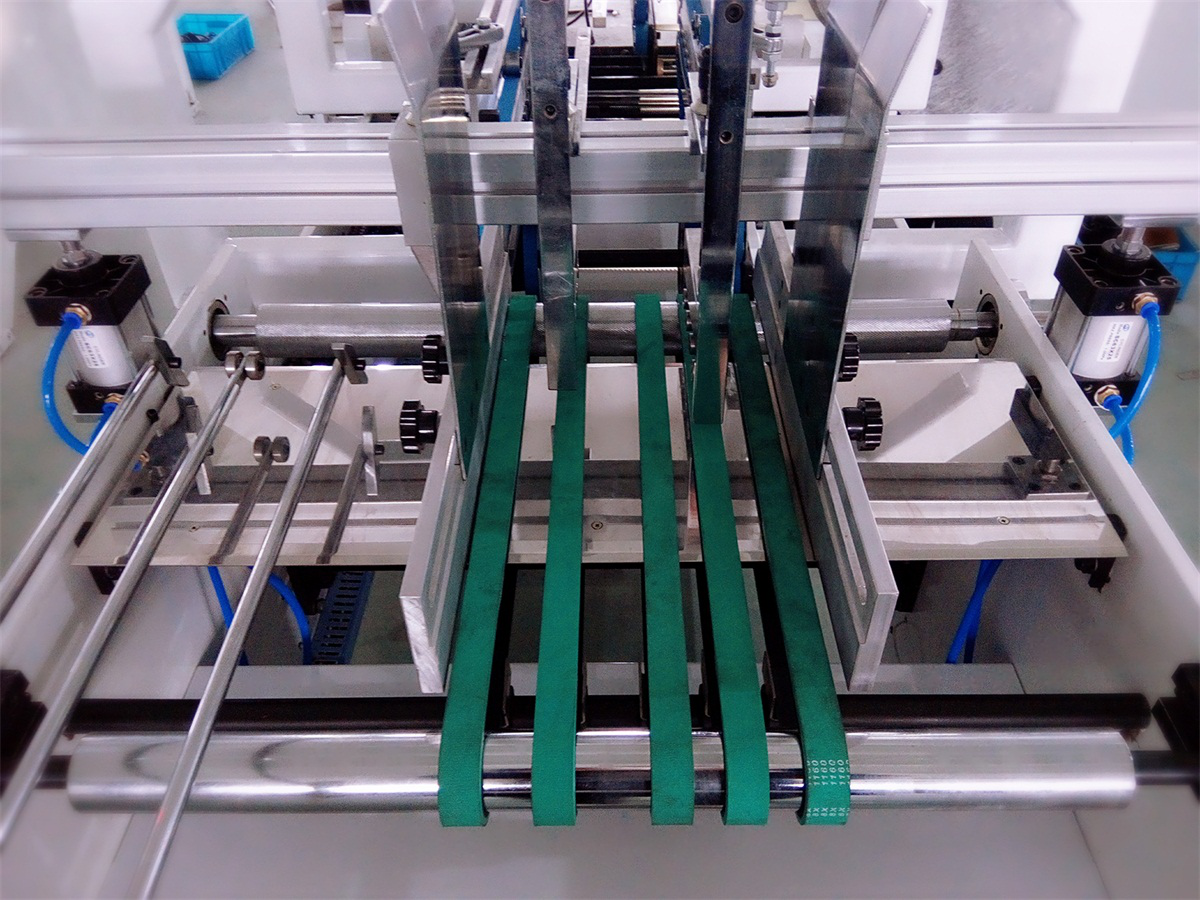

Feeding: |

|

5 adjustable feeding belts to ensure easy adjustment, stable and smoothly feeding Continuously Variable Speeder to ensure feeding internal and stable transmission One-touch Pneumatic knife, easy for the adjustment of feeding belts |

|

|

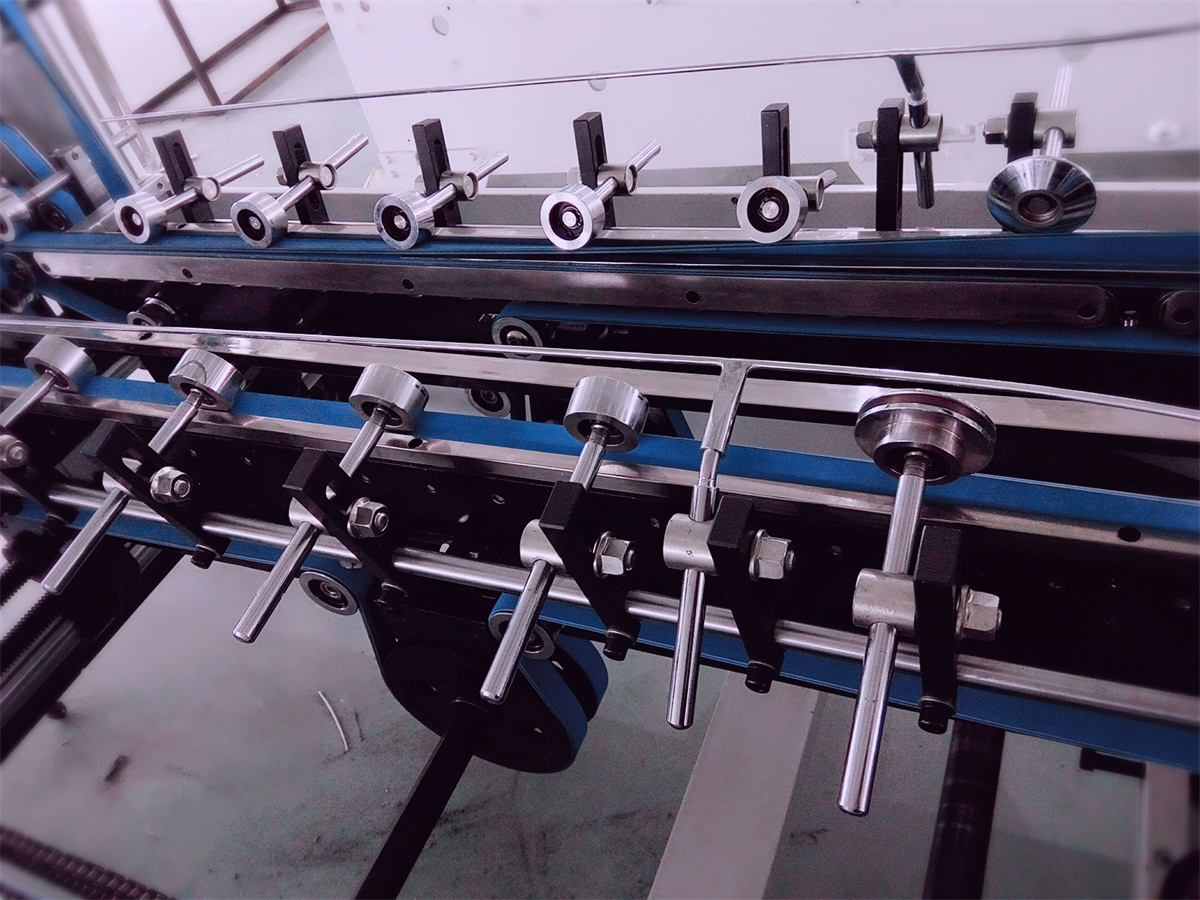

Pre-fold: |

|

Double-board structure with a set of pre-folding knife. Pre-fold angle is 180°and 135°, especially suitable for small but high cartons, more satisfactory while rapid prototyping. |

|

|

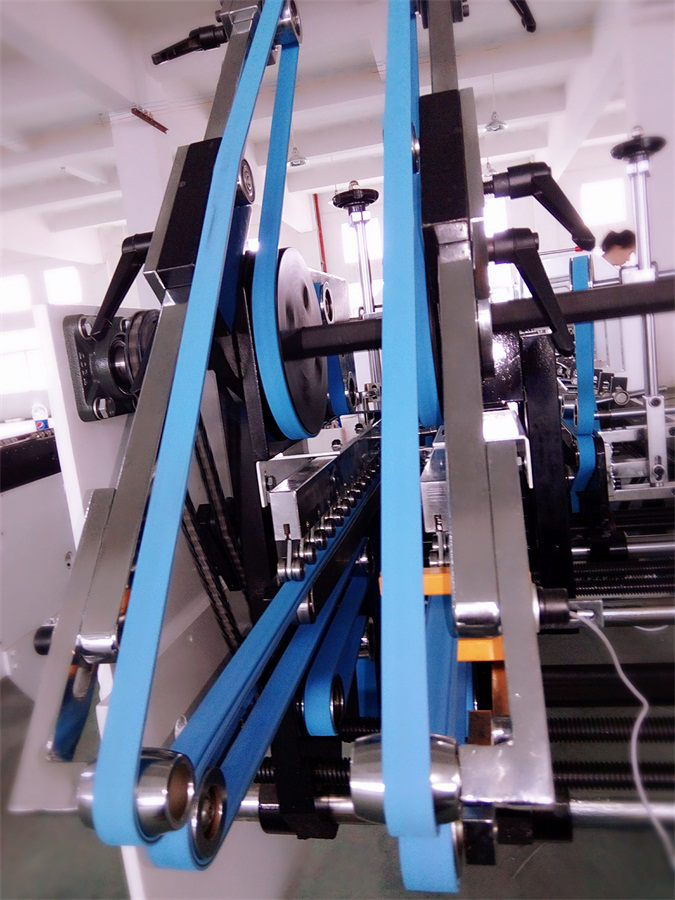

Final Folding: |

|

Lengthened folding to avoid the unevenness while the rapid forming of cartons and make it come to perfection. |

|

|

Trombone part: |

|

2-board structure Two modes for pressing belt speeding: Auto: set distance between boxes, pressing belt speed is the same as the machine, belt removes while sensor detect it. Manual:pressing belt conveys in a fixed speed and machine speed will not put any effect on it. With counting device to count the finished boxes to match with boxes regulating, easy to count and pack |

|

|

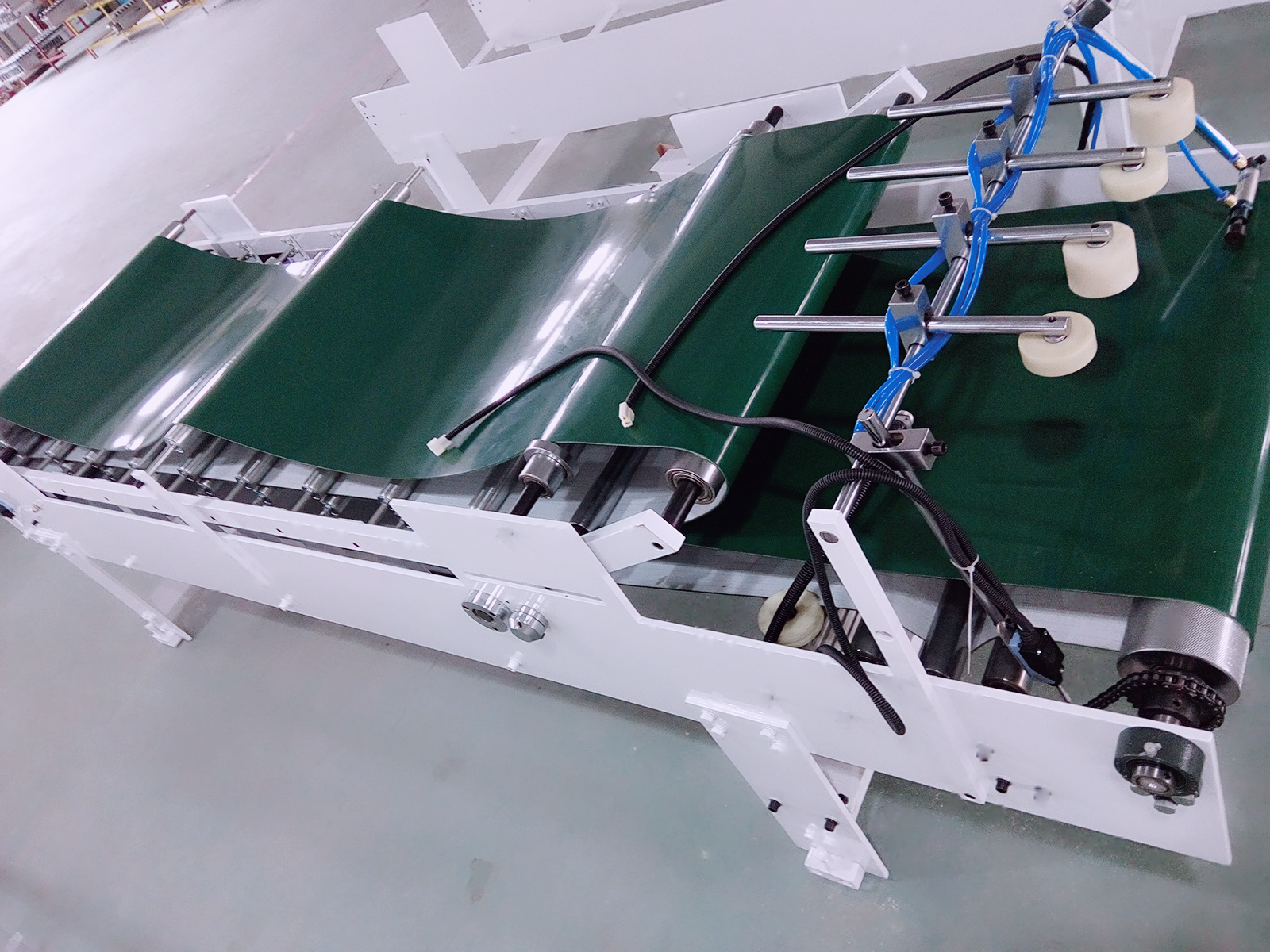

Press/ Conveyor: |

|

Equipped with feeding paper inspection device. Equipped with impacting device to press the paper after accounting and make it easy to pack paper. |

|

Brief introduction |

|

Feeding : Automatic and continuous feeding |

|

Adhesive: Water soluble solid glue |

|

Basic box gluing methods: one side-gluing |

|

Power: 3P380V50HZ |

LTHH-B High Speed Folding Gluing Machine

Product introduction:

Series B Model A 2-fold folding gluing machine is Pre-fold amchine, adopt synchronous belt transmission and electronic continuously variable speeder ,domestic standard electronic components,feeding section adopt mechanic continuously variable, stable and easy to control and operate. It is widely used in food, medicine, cosmetics, stationery and other ordinary cartons, process and perfectly combing the requirements of auto packaging together. (in case of any special function required, we can design according to the customer’s requirement).

Feature introduction:

The Machine consists of 5 sections: feeding, pre-folding , final folding, full-press and transmission.

Technical Data:

|

Name |

LTHH-650B pre-folding Gluing Machine |

| Model |

LTHH-650B |

|

Paper Material |

Cardboard 210-800g |

|

Max. Liner speed |

Max. 220 m/min |

|

Feeding way |

Automatically and continuously feeding |

|

Way of folding |

Fold 1 and fold 3 are 180°, fold 2 and fold 4 are 135°and 180° |

|

Glue Material |

Water-base cold glue |

|

Electric power |

6.0kw 380v |

|

Weight |

2.3T |

|

Over dimension |

8.2x1.3x1.45m |

|

|

Feeding: |

|

5 adjustable feeding belts to ensure easy adjustment, stable and smoothly feeding Continuously Variable Speeder to ensure feeding internal and stable transmission One-touch Pneumatic knife, easy for the adjustment of feeding belts |

|

|

Pre-fold: |

|

Double-board structure with a set of pre-folding knife. Pre-fold angle is 180°and 135°, especially suitable for small but high cartons, more satisfactory while rapid prototyping. |

|

|

Final Folding: |

|

Lengthened folding to avoid the unevenness while the rapid forming of cartons and make it come to perfection. |

|

|

Trombone part: |

|

2-board structure Two modes for pressing belt speeding: Auto: set distance between boxes, pressing belt speed is the same as the machine, belt removes while sensor detect it. Manual:pressing belt conveys in a fixed speed and machine speed will not put any effect on it. With counting device to count the finished boxes to match with boxes regulating, easy to count and pack |

|

|

Press/ Conveyor: |

|

Equipped with feeding paper inspection device. Equipped with impacting device to press the paper after accounting and make it easy to pack paper. |

|

Brief introduction |

|

Feeding : Automatic and continuous feeding |

|

Adhesive: Water soluble solid glue |

|

Basic box gluing methods: one side-gluing |

|

Power: 3P380V50HZ |

Add:LTPM CHINA 2nd Floor,Dongxin Road and 5th Development Road ,Caizhai Industrial Zone, Ruian City, Zhejing Province ,China

Tel:86-0577-65158955 Fax: 86-0577-65158944

Business Phone : 86-0577-65158955

E-mail:info@chinaleadtop.com

About Us

Contact Us

LeadTop Pharmaceutical Machinery Co., LTD 浙ICP备16043185号-1

LeadTop Pharmaceutical Machinery Co., LTD 浙ICP备20003428号-1